Phone: +7 (383) 330-67-71, Fax: +7 (383) 330-80-56, E-mail: bic@catalysis.ru

5 Lavrentiev Ave., 630090, Novosibirsk, Russia

Phone: +7 (383) 330-67-71, Fax: +7 (383) 330-80-56, E-mail: bic@catalysis.ru

5 Lavrentiev Ave., 630090, Novosibirsk, Russia

30 November 2021

Researchers of Boreskov Institute of Catalysis with support from the Russian Science Foundation developed a unique catalyst for obtaining hydrogen-containing gas from diesel fuel. This technology would efficiently convert the chemical energy of motor fuel into electric power with the use of electrochemical generators.

Vladislav Shilov, junior researcher of Boreskov Institute of Catalysis, said that there is still no commercially available product at the market – a catalyst of conversion of diesel fuel and, correspondingly, the fuel processor that would allow obtaining hydrogen-containing gas for powering the fuel cells.

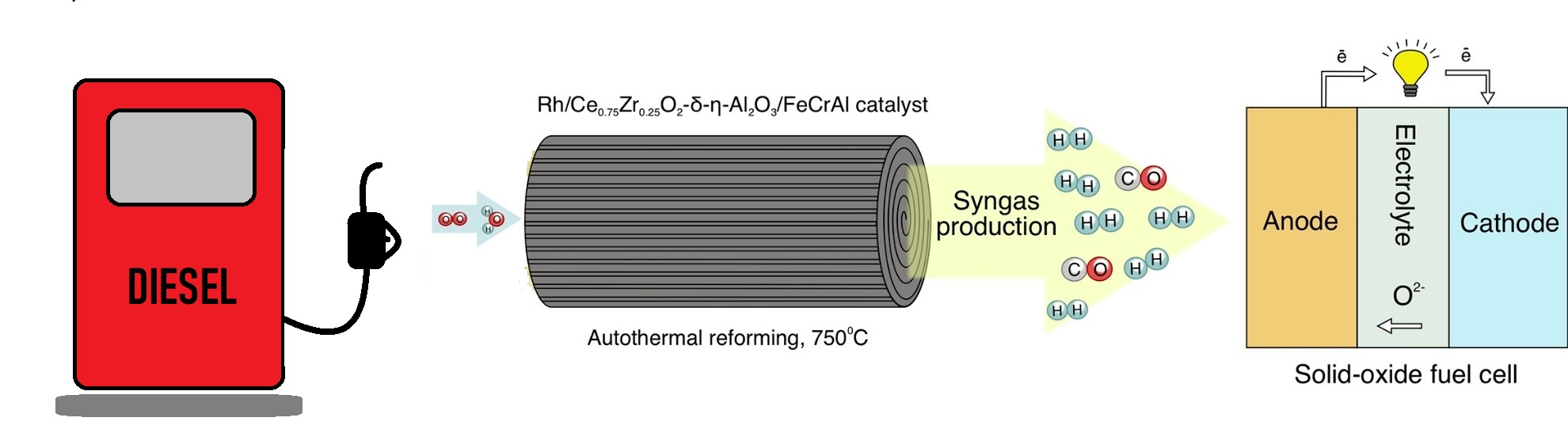

The scientists developed a composite rhodium-containing catalyst within the projects of the Russian Science Foundation “Development of structured catalyst and fundamental basics for oxidizing conversion of diesel fuel into synthesis gas for using in the fuel cell-based power plants”.

The active component of the catalyst is resistant to sintering at high (about 900°C) temperatures. The fechral (FeCrAl alloy) grid is used as a structured support for alumina. The needle-like structure of the alumina crystals chemically bonded with the metal support increases the adhesive properties of the surface and provides the mechanic strength of the secondary catalytic layer. Then a mixed cerium and zirconium oxide is applied onto the surface that participated in the activation of molecules of water and oxygen and increases the resistance to carbonization. The final stage of synthesis is the supporting of rhodium nanoparticles of 1-2 nm in size that are responsible for the activation of molecules of hydrocarbons.

“The catalyst that we obtained is resistant to sintering and carbonization. We have tested it in the conversion of commercial diesel fuel. It demonstrated a very high activity and did not lose it after 200 h of operation”, explained Vladislav Shilov.

According to the young scientist, the complications in creating the catalyst are due to the complexity of diesel fuel – it consists of several hundreds of substances that belong to various classes of organic compounds and feature different reactivity. Another complication is the choice of the best reaction conditions with the absence of carbonization of the catalyst because of undesired side processes. This leads to the necessity of conducting conversion in a rather narrow range of temperatures and reaction conditions.

“We’re developing a fuel processor in which the catalytic reaction of air-steam conversion of diesel fuel into synthesis gas occurs, syn-gas being the fuel for supplying the solid oxide fuel cells. An advantage of the technology of obtaining electric power from diesel fuel in the fuel cell-based electrochemical generators is a high degree of efficiency, 35% to 65%, which several times exceeds the degree of efficiency of diesel or petroleum low-power generators. Other advantages include environmental safety, noiseless operation, absence of moving parts, which means that there’s no need for maintenance for a long time”, said Vladislav Shilov.

The fuel processor requires not only the development of catalyst but also the solution of various engineering problems. These problems are related to the optimization of supplying the reagents, their mixing, and construction of the reactor in general.