|

Provides economic and ecologically friendly fuel combustion, low metal consumption, reliable operation. Heating of greenhouses, warehouses, working and service areas.

|

|

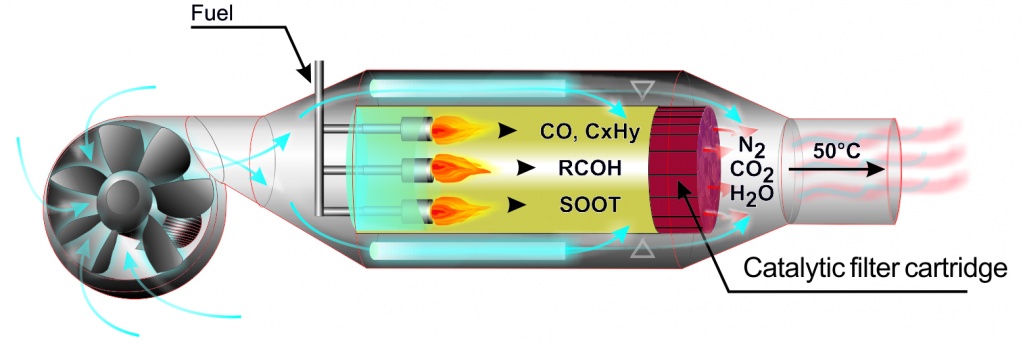

| The operation is based on two-stage combustion of liquid or gaseous (natural gas) fuel. | |

|

The first stage is fuel flaring. The produced fuel gas is mixed with air using a centrifugal vent to reach the required temperature and fed to the second chamber bearing a honeycomb monolith catalyst. At 400–800°C, the catalytic cartridge provides the full oxidation of carbon monoxide and products of fuel incomplete burning, as well as reduction of nitrogen oxides.

A series of 0.03 to 3.0 MW heat power units in a variety of sizes and shapes have been developed |

|

| Specifications (a 90 kW air heater) | |

| Natural gas flow rate, m3/h | 9.1 |

| Air productivity, m3/h | 5000 |

| Air heating, °C, no less | plus 50 |

| Heating efficiency,% | 99 |

| Content of toxic compounds in the heated outlet air is below MAC of the work space. | |||

| These are, mg/m3 | MAC* | in fact | |

| СОx | 20 | 13 | |

| NOx | 5 | 3 | |

| SOx | 10 | 9 | |

| CnHy | 300 | 30 | |

|

* MAC are Russian standards on maximum allowable concentration The units of 100 kW capacity are commercially used in greenhouse farms Russia wide. |

|||

| | |||

| Contacts | |||

| bic@catalysis.ru | |||