|

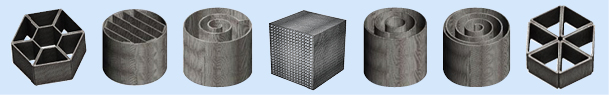

A technology was developed for manufacturing of structured catalytic cartridges of various shapes and sizes. |

| Application area |

|

Abatement of CO, hydrocarbons and volatile organic compounds (VOCs) in waste gases of industrial facilities and power plants. Environmentally efficient fuel combustion. Selective oxidation of hydrogen sulfide to sulfur for the cllean-up of tail gases from Claus plants and in the processes of direct desulfurization of hydrocarbon gases. |

| Advantages |

|

A possibility to create the catalytic beds of any size and shape. A high efficiency of mass transfer at a uniquely low pressure drop. Stability to thermal and mechanical stresses. A possibility of application for treatment of dusty and contaminated reaction flows. |

| Catalyst specifications |

|

Active component |

Application area

|

|

|

Pt (0.05–0.1 wt %) |

Abatement of CO, hydrocarbons and volatile organic compounds (VOCs) in waste gases of industrial facilities and power plants. Operation temperature up to 750 °C, efficiency of VOC removal from waste gases up to 99.99 %. | |

|

CuCr2O4 (3–4 wt % Cu) |

Abatement of CO, hydrocarbons and volatile organic compounds (VOCs) in waste gases of industrial facilities Operation temperature 100–600°C, efficiency of VOC removal from waste gases up to 99.9% | |

|

Fe2O3 (2 wt % Fe) V2O5 (4–8 wt % V) |

Selective oxidation of hydrogen sulfide to sulfur for the cllean-up of tail gases from Claus plants and in the processes of direct desulfurization of hydrocarbon gases. Operation temperature 150–250 °C, gas composition: 0.1-1.5 vol % H2S, 0.5–2 vol % О2, up to 30 vol % water vapor; conversion of H2S up to 100 %, sulfur yield up to 98 %. |

| State-of-the-art | |

|

The technology for preparation of the structure c catalytic systems was tested at the pilot scale

|

|

| We offer |

|

Design and optimization of catalytic reactors based on microfiber catalysts using the computational fluid dynamics method and technological modeling. Manufacturing and supply of experimental batches of the structured catalytic systems for new and existing purification plants. Preparation of basic engineering data for designing new type reactors for purification plants. Arrangement of designing, equipment manufacturing, assembling of facilities and start-up works. Author`s supervision services during operation of the purification plants. |

| Contacts |

|

E-mail: bic@catalysis.ru |